| Catégorie de matériau | Plastique / Matière plastique |

| RXNR | 68-1-S |

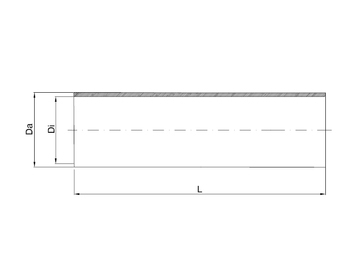

| Désignation | Amiantit - Flowtite GRP jacking pipe PN1 (SN32000) |

| Fabricant | Amiantit Europe |

| DN | 400 |

| Extrémité du tuyau | Extrémité pointue |

| Nom du matériau | Fibre de verre, Résine polyester, Additifs de sable de quartz, Acier inoxydable |

| Couleur (extérieure) | Jaune, Blanc |

| Domaines d'application | Génie civil, Drainage, Ponts, Industrie |

| ID (mm) | |

| Dext (mm) | 427 |

| Épaisseur de paroi (mm) | 28 |

|

The trenchless laying of pipelines with microtunneling is a technology that can no longer be imagined in the management and construction of urban infrastructure and is enjoying growing importance. This high-tech pipe jacking process not only requires high-performance laying technology, but also suitable pipe systems that can cope with the immense physical demands of this technology. For microtunnelling (pipe jacking process), whose area of application extends far into the accessible nominal widths, the reinforced concrete pipe has so far been the "classic": Robust, resilient, but at the same time heavy and massive, it has set the standards for decades, but has so far also defined them Limits of pipe jacking, not least because cement-bound concrete pipes are not the best choice when building mixed water sewers with their potentially highly corrosive liquids. So it is ultimately not surprising that concrete has had a market share of pipes made of glass fiber reinforced plastic in this area of application for years ( GFK) loses. GRP pipes, such as those offered by Amiantit Germany GmbH with "AMIJACK jacking pipes", are not only permanently corrosion and abrasion resistant and therefore a good choice for the transport of aggressive wastewater. They also combine excellent static properties with a comparatively small wall thickness comparatively low weight per meter - especially when compared with reinforced concrete pipes. With the same wall thickness, GRP pipes offer a multiple of the ring stiffness of a reinforced concrete pipe. Or, seen the other way round: GRP offers a defined static load-bearing capacity with a much smaller wall thickness than reinforced concrete - and with significantly less Weight: AMIJACK jacking pipes offer ring stiffnesses from SN 32000 to SN 1000000. The pipe dimensions for GRP pipes from AMITECH are available in nominal sizes from DN400 to DN2400. They are lighter or thinner-walled with the same load-bearing capacity and can therefore usually be installed more easily and quickly than the heavy-weight traditional pipe materials. The forces required to advance a continuously growing pipe string are significantly reduced with GRP jacking pipes, mainly because the external friction of the smooth material is significantly lower than that of concrete. Therefore, when installing the AMIJACK, fewer intermediate pressing stations can be used, a fact that considerably speeds up the entire project process. From a macroeconomic perspective, a GRP-based jacking project can therefore be cheaper than the conventional alternative with the reinforced concrete pipe, which is usually cheaper by the meter. In principle, decision-makers should always keep an eye on the total costs, i.e. calculate material costs and laying costs and take them into account accordingly. Functional description of a tunneling machine The drill head loosens the soil with its tools - cutters, knives, chisels or discs. This then reaches the crusher room. Any stones that may be present are crushed here. In a closed circuit system, a drilling suspension is first pumped into the crusher room, where it is enriched with the soil and is pumped back to the separation plant or processing plant. The separation system then separates drilling suspension (e.g. betonite) and soil. The soil is disposed of and the drilling suspension is pumped back into the crusher room in an environmentally friendly manner. The pipe string can be advanced further with the hydraulic cylinders of the press frame. The position of the machine is checked with a laser beam. The target plate reports the position of the laser point to the machine operator in the control container. Hydraulic cylinders make it possible to control the drill head and thus correct the position. The driver operates the entire system from the control container. Source: Amiantit, www.wipo.krv.de (24.06.2015), www.amiantit.eu |