| Material category | Plastic |

| RXNR | 13-7-S |

| Designation | Amiantit - Flowtite GRP piping systems PN1 (SN2500) |

| Manufacturer | Amiantit |

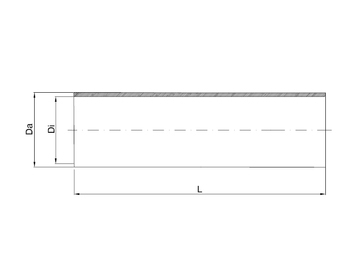

| DN | 350 |

| Pipe end | Spigot |

| Material name | Fiberglass |

| Color (exterior) | Gray, White |

| Applications | Bridges, Industry, Civil Engineering |

| ID (mm) | 366 |

| OD (mm) | 376 |

| Wall thickness (mm) | 5 |

|

Amiantit Europe Amiantit Europe is the European umbrella organization of the Saudi Arabian Amiantit Company SAAC. The multicultural management follows a common vision and coordinates all sales and manufacturing activities of the group within Europe. Many years of extensive experience enable Amiantit Europe to successfully place application-optimized GRP pipe systems for a variety of applications on the market. Taking customer-specific requirements into account, three European plants in Germany, Poland and Spain as well as numerous sales offices within Europe manufacture and sell GRP (glass fiber reinforced plastic) pipes up to a diameter of 4,000 mm. Flowtite GRP pipes have been installed in more than 40 countries around the world. The protected Flowtite GRP system impresses with its excellent long-term behavior and low operating costs over the entire period of use. These advantages are based on the special manufacturing method, excellent weight / size proportions, good chemical resistance and a smooth, corrosion and dirt-resistant inner surface. For the customer, this means lower transport costs, quick assembly, low operating costs and a long life cycle. Production process FLOWTITE pipes are continuously produced on a steel core that is constantly pushing forward. This process corresponds to the current state of the art. The manufacturing process allows the use of continuous fibers in the circumferential direction. In the case of pressure pipes or underground lines, the greatest stresses occur in this direction. The introduction of glass fibers in the circumferential direction enables the production of a higher quality pipe at lower costs. Using this specially developed technology, a very compact composite material is created that combines the positive properties of its three raw materials. Cut and continuous glass fibers in the composite ensure high ring stiffness and thus achieve high axial strengths. To further increase the rigidity, the wall thickness is increased by a quartz sand reinforcement near the neutral axis in the core. With the FLOWTITE resin double loading system, it is possible to apply special resistant, inner resin layers for corrosion-prone applications, while the structural layers and outer areas are made of less expensive resin. Due to the advantages of the winding process, materials such as fiberglass or polyester fleece can be used to improve abrasion resistance and the pipe surface. In order to guarantee a consistently high level of quality, it is of fundamental importance to carefully control the production process. The FLOWTITE continuous fiber winding machine represents the latest state of the art in use and is a leader in GRP pipe production. Put simply, the winding machine consists of a continuous steel band on a spindle made of rods that are connected to form a cylinder. When the spindle rotates, the friction pulls the steel belt taut and roller bearings allow axial movement, so that the entire shell moves continuously forward in a spindle-shaped manner until it returns. While the mold core is moving, the starting materials are precisely dosed and applied. Electronic sensors ensure constant feedback of the production parameters so that the various loading systems always apply the correct amount of material. This ensures that the necessary amount of material to build up the layers is continuously applied during production. First the release film, followed by different glass fiber materials, surrounded by a polyester resin matrix. The structural layers contain only glass and resin, while the core contains pure quartz sand. The tube is created by the permanent application of the raw materials on the continuous winding core. Flowtite GRP pipe systems have the following advantages, among others: - Long shelf life without additional corrosion protection - Low weight and long tube lengths enable easy transport, handling and installation - Tight connections through the use of easy-to-use standard Flowtite couplings with Reka seals - Extremely smooth pipe wall Application areas: Sewer pipelines • Pressure pipelines • Drinking water pipes • Storage space systems • Hydropower pipes • Drinking water storage tanks • GRP special profiles • Industrial pipes • Manholes • Well pipes • Bridge pipes • Jacking pipes Source: www.flowtite.com, www.wikipedia.de, www.amiantit.eu |